Types and characteristics of metallization of zirconia ceramic rods

2020-09-16(2010)Views

The zirconia ceramic rod is processed by isostatic pressing process to form a uniform, dense and smooth ceramic layer and transition layer at high temperature and high speed.

Zirconium oxide ceramic rod metallization is to paste the ceramic rod on the inner wall of the metal with high temperature resistant strong adhesive, and form a strong anti-wear layer after heating and curing. The production process of this product is relatively simple, the production cycle is short, and the cost is relatively low. Technical specifications: Mingrui Ceramics has ceramic rods of various sizes, and can also be customized according to customer needs. Metallized ceramic rods are basically not limited in size, and diameters from 0.5mm to 160mm, and even larger can be produced.

Ceramic rod perforation is to paste the ceramic rod with a hole in the middle to the inner wall of the metal with high temperature resistant strong glue, and at the same time, the ceramic is firmly welded to the inner wall of the steel sleeve through the small hole with the spot welding process. To protect the solder joints, screw on the ceramic cap. Each porcelain rod is not only close to each other, but also forms a corresponding angle, so that the porcelain rods are tightly connected and there is no gap; when the last one of a circle is tightly embedded, a 360 mechanical self-locking is formed between the porcelain rods force. The production process of this kind of product is relatively complicated, the production cycle is long, and the cost is high.

One-piece wear-resistant ceramic rods are assembled by firing the ceramic rods as a whole and pouring them into the steel sleeve with special fillers. The ceramic rod has a smooth inner wall, good airtightness, and good wear resistance and corrosion resistance. But this kind of product has a long production cycle and high cost.

The composite rods fully utilize the high strength, toughness, impact resistance, welding performance of the metal rods, and the high hardness, high wear resistance, corrosion resistance and heat resistance of the corundum porcelain, which overcomes the low hardness of the metal rods, poor wear resistance and ceramics. Characteristics of poor toughness. Therefore, the composite rod has good comprehensive properties such as wear resistance, heat resistance, corrosion resistance, mechanical and thermal shock resistance, and good weldability.

Because the zirconia ceramic rod has wear resistance, corrosion resistance and heat resistance, it can be widely used in electric power, metallurgy, mining, coal, chemical and other industries as corrosive media, and it is an ideal wear-resistant ceramic rod.

+MoreRelated Suggestion

-

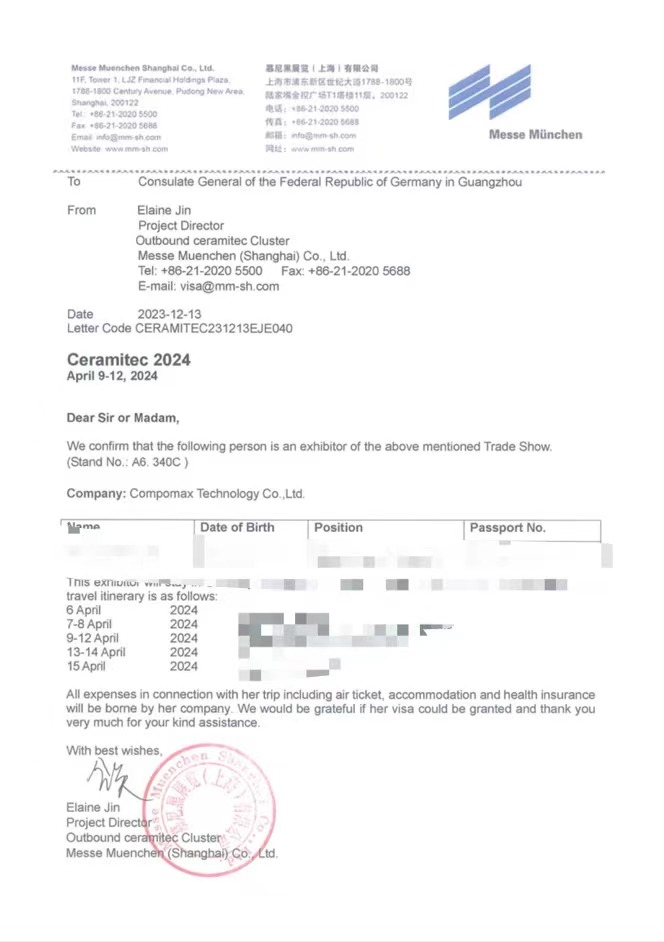

Compomax to Attend Ceramitec 2024

As a leading manufacturer of technical ceramics in China, Co...

-

PWTC Expo, the Exhibition Venue of CERAMICS CHINA 2024

From June 25-28, 2024, the 38th edtion of CERAMICS CHINA wil...

-

The eight application fields of zirconia ceramics in modern life

The non-signal shielding of zirconia ceramics is resistant t...

-

Application of Zirconia Ceramic Conversion Coating in Automobile Coating

In the field of automotive coating, phosphating is the most ...

0755-27688979

Service Hotline:0755-27688979

Phone:0086 13823743080

Fax:

Email:apricot@cpmic.com

Address: